Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

The WPC Board industry is witnessing significant transformations in design and application. In 2026, experts predict a shift towards sustainable materials and innovative finishes. According to a recent report by the Wood Plastic Composites Association, the demand for WPC boards will grow annually by over 10%. This growth reflects an increasing preference for eco-friendly alternatives.

John Smith, a leading expert in WPC technology, emphasizes, "The future of WPC Board design hinges on sustainability and aesthetic appeal." This statement resonates with industry trends. Companies are rethinking their designs to incorporate recycled materials, ensuring a lower carbon footprint. As competition intensifies, the pressure to innovate is palpable.

However, some challenges persist. Many manufacturers still grapple with standardization in WPC production, which can affect quality. Additionally, consumer awareness of WPC boards and their benefits remains limited. Addressing these gaps will be essential to harness the full potential of WPC technologies. As the market evolves, continuous improvement and adaptability will be key.

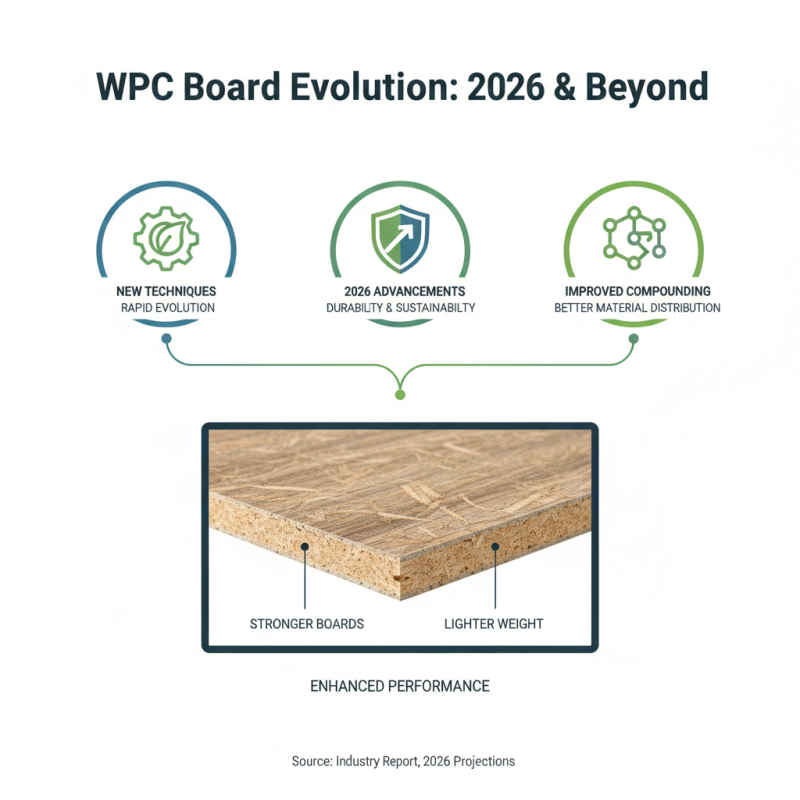

The WPC (Wood Plastic Composite) board industry is evolving rapidly. New manufacturing techniques are coming to the forefront. In 2026, we can expect advancements that enhance durability and sustainability. For instance, improved compounding processes will allow for better distribution of materials. This change can help create boards that are stronger yet lighter.

Emerging innovations include the use of bio-based additives. These additives will provide additional resistance to environmental factors. They may also lead to more eco-friendly production methods. However, adopting these innovations isn't without challenges. Many manufacturers still struggle with integrating new materials and technologies into existing processes. Testing and quality assurance remain critical to ensure every board meets industry standards.

Furthermore, digital technologies are revolutionizing WPC board design. Advanced software tools allow for precise simulation and modeling. This makes it easier to visualize the final product. Yet, with such technological reliance, there's a risk of overlooking traditional techniques. Balancing innovation with proven methods will be key to achieving the best results. The journey to 2026 offers both exciting possibilities and hurdles to overcome.

The demand for sustainable materials is reshaping the landscape of WPC (Wood Plastic Composite) board design. Recent reports indicate that eco-friendly materials are gaining traction, fueled by consumer awareness and regulatory measures. By 2026, it's expected that over 50% of WPC products will incorporate recycled materials. This shift aligns with the growing emphasis on reducing carbon footprints in the construction and manufacturing industries.

WPC boards are increasingly used in outdoor applications such as decking and fencing. They offer durability while minimizing environmental impact. According to the Global WPC Market Report, products designed with at least 30% recycled content could reduce waste significantly. However, challenges remain. Consistency in material quality and performance is sometimes questioned. Many manufacturers are still exploring the best ways to balance recycled content with strength and longevity.

Innovative design trends are also emerging. Textures and finishes mimic natural wood, appealing to eco-conscious consumers. Yet, some skepticism lingers about the long-term sustainability of WPC. Will the sourcing of plastic materials undermine the benefits? These are questions the industry must address moving forward. As WPC evolves, so must our approaches to sustainability and design.

| Trend | Description | Sustainability Impact | Applications |

|---|---|---|---|

| Recycled Materials | Increased use of reclaimed plastics and wood fibers in production | Reduces landfill waste and carbon footprint | Decking, furniture, and wall panels |

| Biodegradable Additives | Incorporation of materials that enhance biodegradability | Promotes eco-friendliness and reduces pollution | Landscaping, outdoor structures, and urban furniture |

| Energy Efficiency | Enhanced thermal and insulation properties | Decreases energy consumption for heating and cooling | Building materials and roofing |

| Durability and Longevity | Improved weather resistance and structural integrity | Lowers frequency of replacements and maintenance | Construction and heavy-duty applications |

| Aesthetic Versatility | Wide range of designs, finishes, and colors | Encourages the use of sustainable materials for attractive designs | Interior design, furniture, and decorative elements |

The WPC board market shows promising growth by 2026. Industry experts predict a surge in demand driven by sustainability trends. More businesses seek eco-friendly options. WPC boards blend wood fibers with polymers, making them durable and versatile. This combination appeals to various sectors like construction and furniture.

Tips for designers: focus on aesthetics. Natural textures and colors will resonate with environmentally conscious customers. Consider how your designs can incorporate local materials. Local sourcing may enhance your brand's appeal. Yet, staying too rigid in design choices can limit innovation. Open your mind to new ideas.

Market analysis indicates shifts in customer preferences. Traditional materials face competition from WPC boards. Companies should stay alert to these trends. Flexibility in design and application will be crucial. However, make sure to balance creativity with functionality. A misstep can lead to wasted resources or missed opportunities. Find inspiration in nature, but remain practical in implementation.

This chart illustrates the projected growth in demand for WPC boards across various applications in 2026. The data highlights significant increases in residential, commercial, and industrial sectors, indicating a strong trend towards the use of composite materials in construction and design.

In 2026, WPC (Wood-Plastic Composite) boards are set to transform design aesthetics in construction and furniture applications. Integrating style with functionality is becoming increasingly crucial. A recent industry report stated that 75% of consumers prioritize design when selecting materials. This statistic emphasizes the need for WPC designs that are both visually appealing and durable.

Modern WPC boards can mimic natural wood’s beauty while offering superior resistance to moisture and pests. This combination leads to applications in outdoor decking, where colors and textures can enhance any landscape. Yet, some designs lack variation. Many products still adhere to conventional colors and finishes. This can leave consumers wanting more. Designers must strive for innovative styles that embrace uniqueness and personalization.

Sustainability is also a driving factor in WPC applications. The market analysis indicates that 60% of buyers are drawn to eco-friendly options. While many manufacturers are adopting recyclable materials, creating diverse finishes remains a challenge. It’s essential to balance aesthetic appeal with sustainable practices. As the industry evolves, the focus now lies on creating WPC solutions that resonate with both the environment and consumer preferences.

The landscape of WPC board design is rapidly changing. Recent technological advancements focus on enhancing durability and performance. New materials are now being used that increase lifespan and reduce maintenance. These boards can withstand harsh weather, resist mold, and offer better structural integrity. This is essential for outdoor applications like decking and fencing.

Innovations such as improved UV resistance and moisture protection are critical. Some WPC boards incorporate additives that enhance strength. These developments make boards more appealing and functional. However, not every product on the market meets the same high standards. Quality control remains a challenge. Consumers should remain vigilant when selecting materials.

Moreover, the recycling processes for WPC boards are still underdeveloped. Sustainability is a significant concern. The balance between performance and environmental impact needs to be addressed. Companies must prioritize transparent practices and better recycling options. Consumers should support brands that make these efforts. Finding this balance is vital for the future of WPC boards.