Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

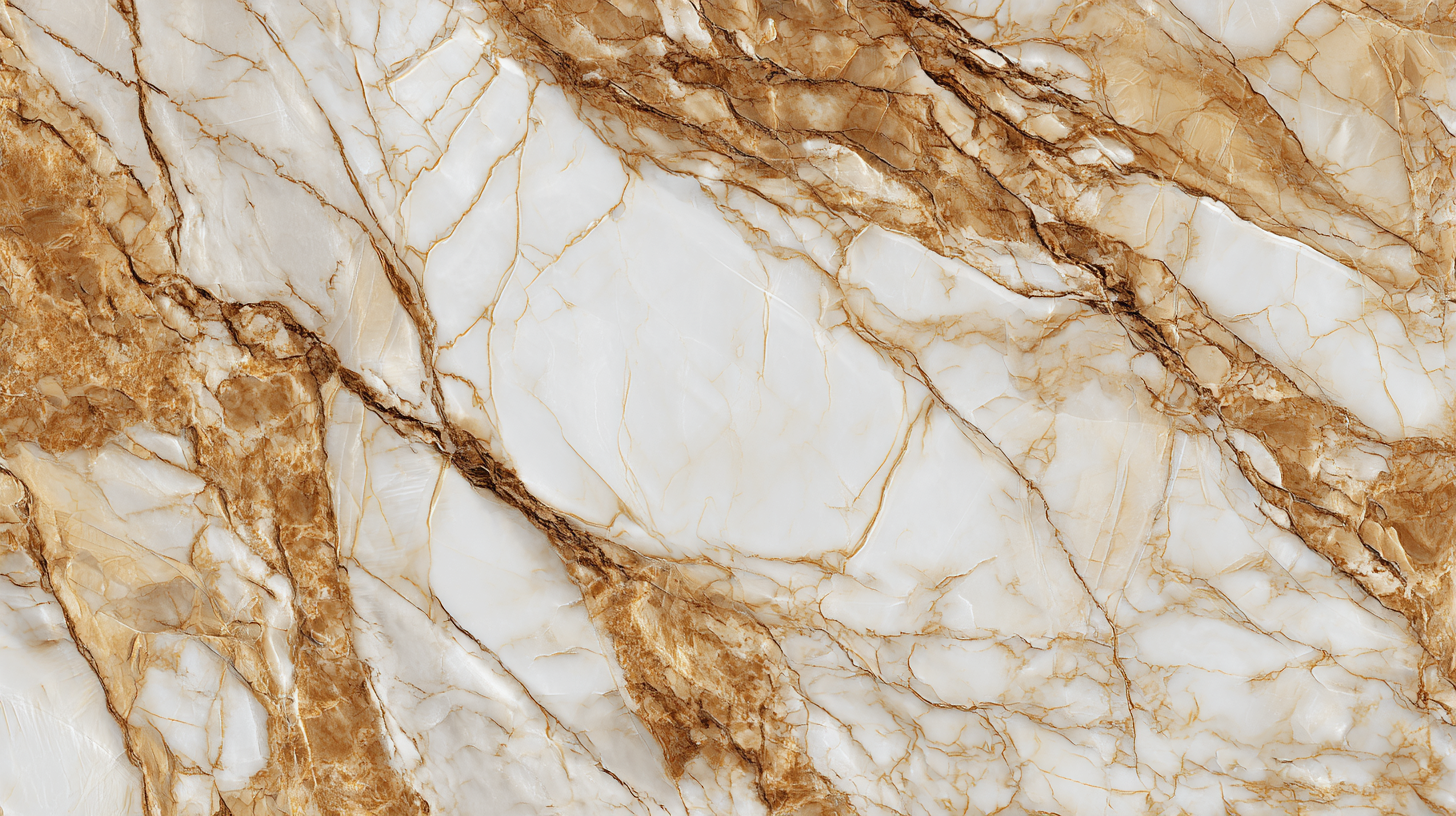

In recent years, the demand for high-quality UV Marble Sheet PVC has surged, driven by its versatility and aesthetic appeal in various applications, from interior design to commercial spaces. According to a report by MarketsandMarkets, the global PVC market is projected to reach USD 69.2 billion by 2026, with UV Marble Sheet PVC being a significant contributor to this growth due to its durability, ease of maintenance, and eco-friendliness. As businesses engage in global sourcing to meet consumer demands, selecting the best UV Marble Sheet PVC becomes paramount. This guide aims to equip you with the essential tips and insights needed to make informed sourcing decisions in an increasingly competitive market, ensuring that you choose materials that not only meet quality standards but also align with your specific project requirements.

When selecting UV marble sheet PVC materials for your global sourcing needs, there are several critical factors to consider. First and foremost is the durability of the material. Research indicates that UV stabilizers play a significant role in enhancing the longevity of PVC products. For instance, studies on equilibrium leaching have highlighted that UV326, UV328, and other stabilizers significantly reduce degradation under intense UV exposure, ensuring that the materials maintain their aesthetic appeal and structural integrity over time.

Another essential factor is the application environment. For outdoor settings where exposure to fluctuating temperatures and humidity levels is high, robust UV protection is vital. The best UV marble sheet PVC should not only be resistant to yellowing and cracking but also able to withstand extreme weather conditions. According to industry reports, selecting materials with over 90% UV resistance can lead to a decrease in maintenance costs and an increase in the lifespan of the product. Additionally, consider the thickness and flexibility of the sheets, as these attributes can affect installation ease and overall performance in various applications, from furniture to decorative uses.

When selecting the best UV marble sheet PVC for your global sourcing needs, understanding the different grades available in the market is crucial. UV marble sheet PVC comes in various qualities, each catering to specific applications and budget constraints. Higher-grade sheets offer enhanced durability, UV resistance, and better aesthetic appeal, making them suitable for high-end projects. Conversely, lower-grade options may suffice for temporary solutions or less demanding environments.

In October 2025, the market for UV sheets, including marble sheet PVC, has seen varying price trends. These polycarbonate sheets are valued for their versatility in applications ranging from roofing to skylights and interior partitions. When sourcing these materials, it’s essential to consider the specific requirements of your project and how different grades can impact both performance and cost. By carefully evaluating the quality and characteristics of various UV marble sheet PVC options, you can make a well-informed decision that aligns with your project needs.

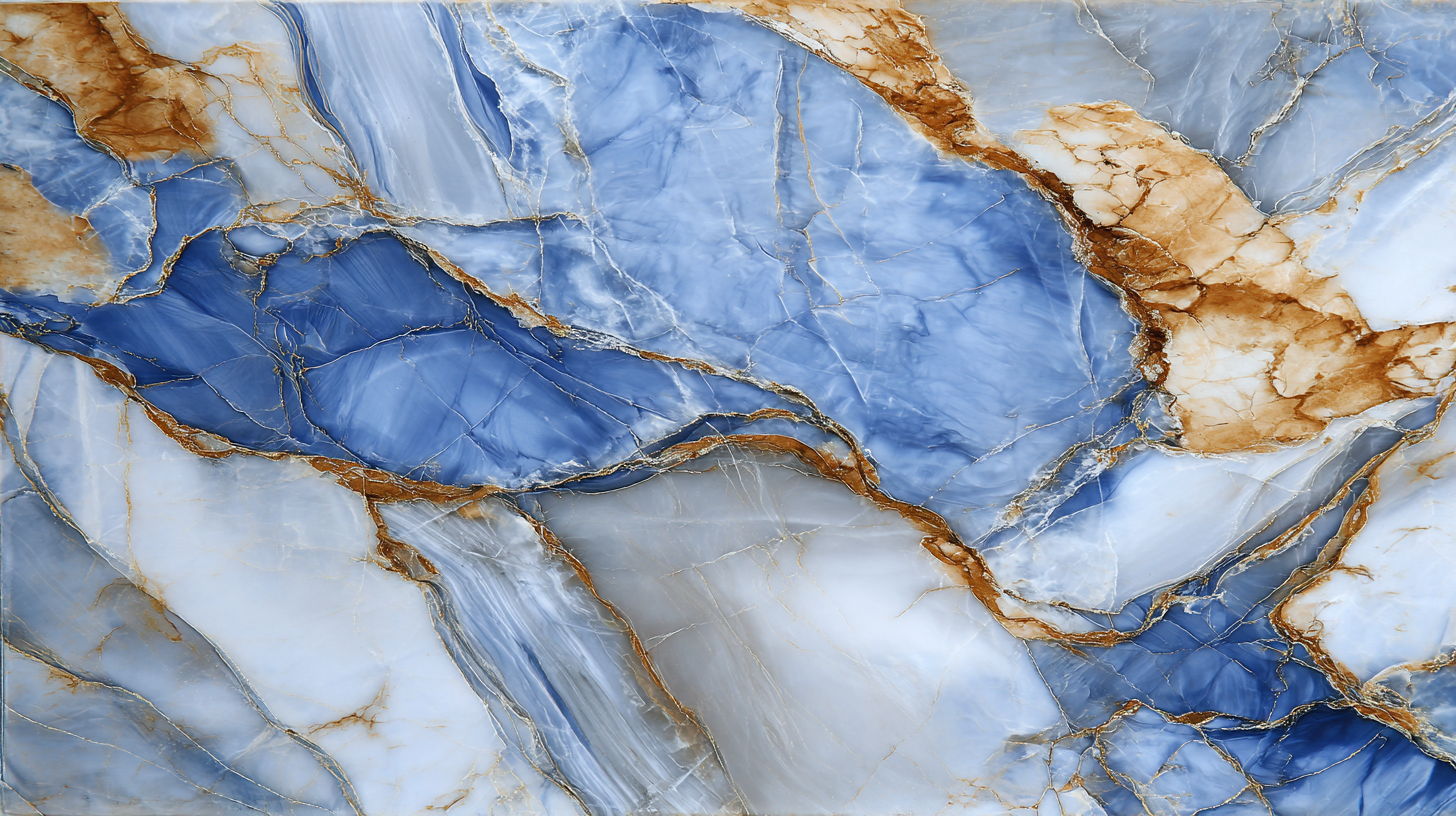

When sourcing UV marble sheet PVC for international markets, evaluating supplier reliability is essential for ensuring product quality and minimizing risks. Start by researching potential suppliers through industry trade shows, online platforms, and relevant certifications. Verify their operational history and customer reviews to gauge their reputation. A reliable supplier should have a track record of consistent delivery, quality, and adherence to international standards, which significantly impacts your business's performance.

Another crucial factor in assessing supplier reliability is their communication and responsiveness. Effective communication indicates a supplier's commitment to customer service and their ability to handle your project requirements. During initial interactions, pay attention to how promptly they respond to inquiries and how well they address your concerns. Additionally, consider visiting their facilities if possible, as this can provide firsthand insight into their manufacturing processes and overall reliability. By taking these steps, you can confidently select a supplier that aligns with your sourcing needs and fosters a successful partnership.

When budgeting for UV marble sheet PVC purchases, it's crucial to consider both the initial costs and long-term benefits. The global market for PVC products is experiencing significant growth, with the PVC footwear segment projected to expand from USD 59.2 billion in 2025 to USD 90.2 billion by 2035, demonstrating a robust CAGR of 4.3%. This growth underscores the increasing demand for high-quality PVC materials, making it essential to analyze your sourcing needs comprehensively.

Tips for your cost analysis: First, evaluate the quality and durability of the UV marble sheet PVC. Investing in premium materials may result in lower maintenance costs over time. Second, compare pricing from different suppliers while taking transport and import duties into account, as these can heavily influence your total expenditure. Lastly, consider the environmental impact of your materials; opting for sustainable options could enhance your brand's reputation and align with broader market trends focused on sustainability, such as those highlighted in recent infrastructure initiatives aimed at fostering local resource management.

| Supplier Country | Material Thickness (mm) | Sheet Size (cm) | Cost per Sheet ($) | Lead Time (weeks) |

|---|---|---|---|---|

| China | 3 | 120 x 240 | 30 | 4 |

| India | 2 | 122 x 244 | 28 | 5 |

| Vietnam | 3 | 120 x 240 | 32 | 6 |

| Turkey | 4 | 125 x 250 | 35 | 3 |

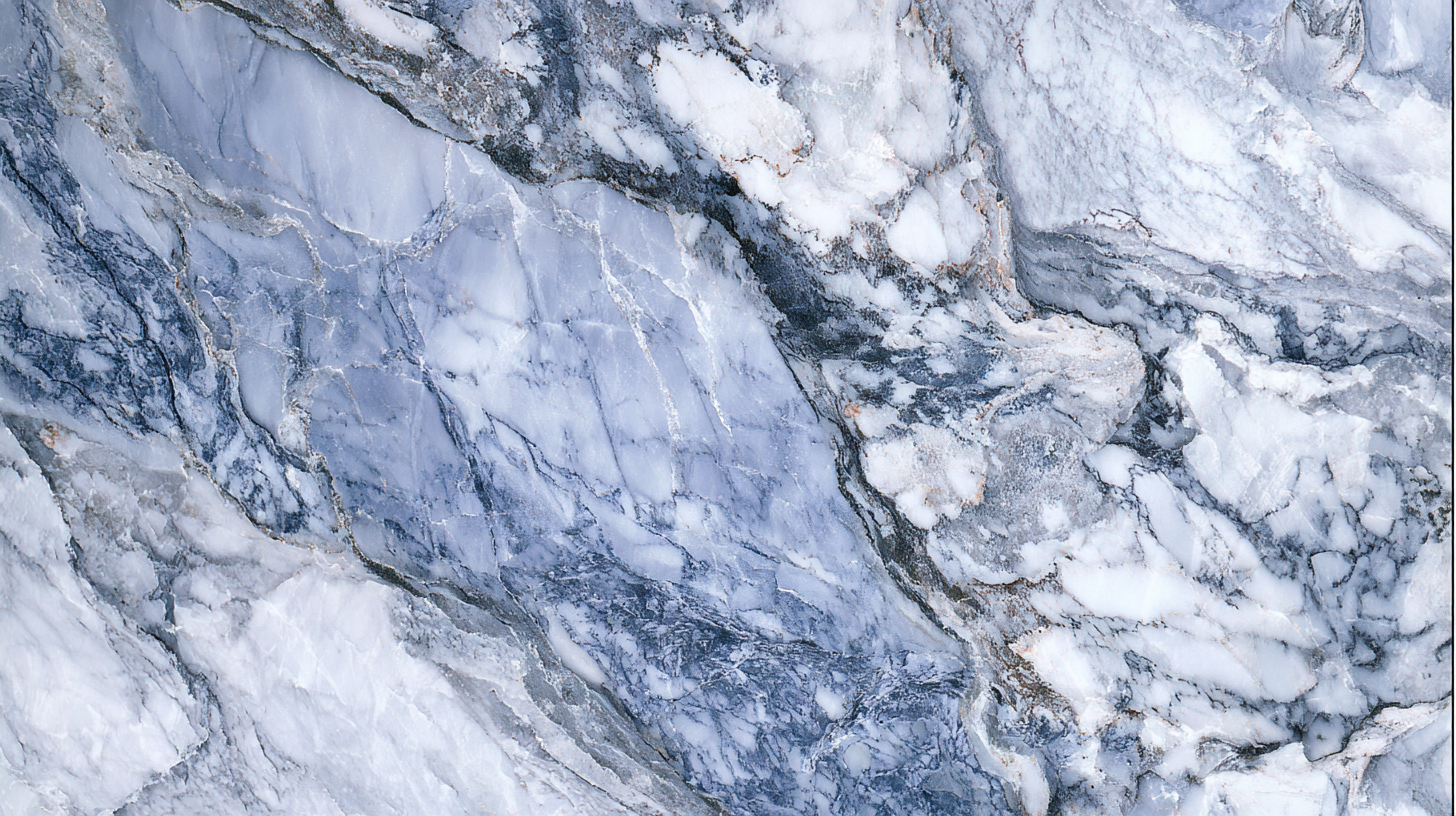

Sustainability in manufacturing has become an essential aspect of the production process, particularly in the creation of UV marble sheet PVC. As the global market shifts towards eco-friendly materials, manufacturers are adopting practices that minimize environmental impact while maintaining product quality. This involves using recycled materials, reducing energy consumption, and implementing waste management systems to ensure that by-products are handled responsibly. By prioritizing sustainability, companies not only meet regulatory standards but also cater to the growing consumer demand for environmentally responsible products.

In choosing UV marble sheet PVC for your sourcing needs, it’s crucial to evaluate the sustainability practices of potential suppliers. Look for certifications that indicate adherence to recognized environmental standards, such as ISO 14001. Additionally, inquire about their production processes—manufacturers utilizing water-based adhesives and dyes or those that have invested in renewable energy sources demonstrate a commitment to reducing their carbon footprint. By aligning your sourcing decisions with sustainable practices, you can support ecological initiatives while providing high-quality materials for your projects.