Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

In the ever-evolving landscape of construction and design materials, UV PVC Marble Sheets have emerged as a premium choice for architects, interior designers, and builders alike. As the demand for high-quality, aesthetically pleasing, and durable materials continues to rise on the global stage, understanding how to identify reliable manufacturers of UV PVC Marble Sheets becomes paramount. This blog delves into expert solutions for discerning premium suppliers who can not only meet stringent quality standards but also contribute to sustainable practices. With China leading the charge in producing these innovative sheets, exploring the nuances of selecting top manufacturers will empower industry professionals to make informed decisions that enhance their projects and ensure satisfaction in a competitive market. Join us as we uncover the keys to unlocking excellence in UV PVC Marble Sheets, where quality truly wins in the global marketplace.

When searching for premium manufacturers of UV PVC marble sheets, it's essential to recognize key characteristics that set them apart from their competitors. One critical aspect is the quality of raw materials. Premium manufacturers typically source high-grade PVC and UV stabilizers that ensure durability, fade resistance, and longevity. This not only enhances the aesthetic appeal of the final product but also guarantees that it can withstand various environmental conditions.

Another distinctive feature of top-tier manufacturers is their focus on advanced technology and innovation in production. They often utilize state-of-the-art machinery and techniques to ensure precision and consistency in their products. Furthermore, premium manufacturers invest in rigorous quality control processes, conducting thorough inspections at various stages of production. This commitment to quality assurance not only elevates the standard of the UV PVC marble sheets but also builds trust with customers who seek reliable and long-lasting solutions for their projects.

The market for UV PVC marble sheets is evolving rapidly, and several key industry trends are expected to shape its trajectory in 2025. One of the most significant trends is the increasing demand for eco-friendly materials. As consumers become more environmentally conscious, manufacturers are focusing on sustainable production processes and raw materials. This shift not only helps in reducing the carbon footprint but also appeals to a broader audience seeking green building materials.

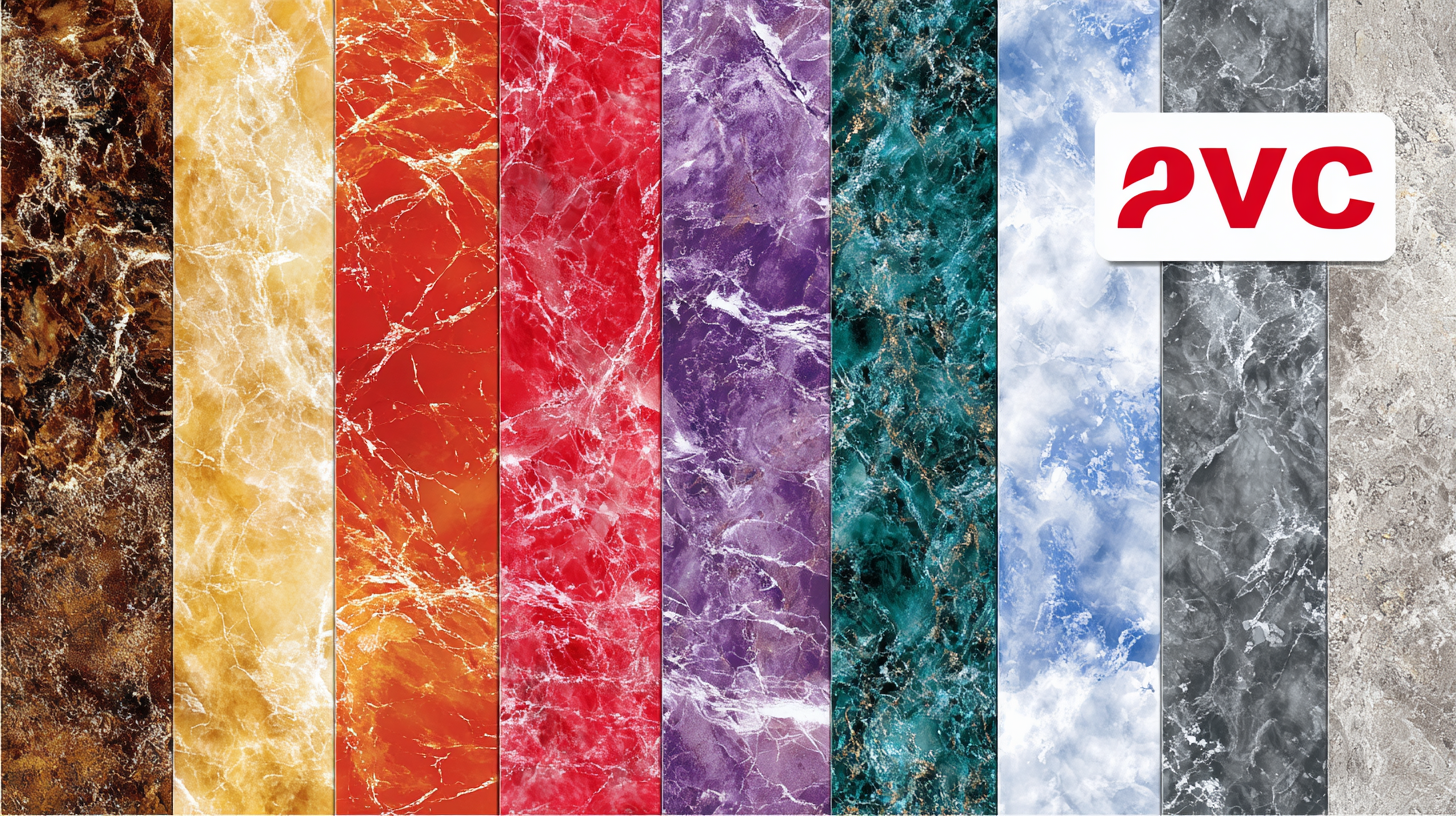

Another trend influencing the future of UV PVC marble sheets is the integration of advanced technology in manufacturing. The use of digital printing techniques and enhanced UV coating processes is allowing manufacturers to produce more vibrant and durable products. This technological evolution not only improves product quality but also enables customization, catering to various design preferences. As a result, customers can enjoy a wider range of colors, patterns, and textures, making UV PVC marble sheets an attractive option for modern interior design.

Another trend influencing the future of UV PVC marble sheets is the integration of advanced technology in manufacturing. The use of digital printing techniques and enhanced UV coating processes is allowing manufacturers to produce more vibrant and durable products. This technological evolution not only improves product quality but also enables customization, catering to various design preferences. As a result, customers can enjoy a wider range of colors, patterns, and textures, making UV PVC marble sheets an attractive option for modern interior design.

Finally, the rise of online marketplaces and e-commerce is reshaping how consumers access these materials. With more buyers turning to digital platforms for their purchases, manufacturers are required to optimize their supply chain and enhance customer experience online. This trend not only increases competition but also encourages innovation in marketing strategies, ultimately benefiting consumers with better choices and prices.

Evaluating the quality of UV PVC marble sheets is crucial for manufacturers and consumers alike. First, consider the sheet's thickness, which is often an indicator of durability. According to a report by the International Association of Plastics Manufacturers, sheets with a thickness of 2-3 mm generally offer a better balance of flexibility and sturdiness, making them suitable for various applications.

Additionally, examining the surface finish is essential; premium sheets typically feature a high-gloss finish that not only enhances aesthetic appeal but also contributes to longevity, as they are more resistant to scratches and stains.

Another important aspect is the chemical composition of the UV PVC material used. A study published in the Journal of Materials Research highlights that sheets with low volatile organic compound (VOC) levels are preferable as they are safer for indoor environments.

Manufacturers should provide certifications to support their claims regarding VOC emissions and other material safety standards. Furthermore, an evaluation of the supplier's reputation and reliability can provide additional assurance; industry reports indicate that suppliers with ISO 9001 certification are more likely to produce consistent, high-quality products. By focusing on these key factors, buyers can make informed decisions when selecting UV PVC marble sheets.

The digital transformation in manufacturing has significantly influenced the quality of UV PVC marble sheets, paving the way for a new era of production methods. Advanced technologies such as automation, artificial intelligence, and data analytics have revolutionized the manufacturing landscape. By adopting these innovations, premium manufacturers can enhance precision and consistency, resulting in high-quality products that meet market demands.

Moreover, digital transformation allows for improved quality control processes. With the implementation of real-time monitoring systems and predictive analytics, manufacturers can identify potential defects early in the production cycle. This proactive approach not only minimizes waste but also ensures that each UV PVC marble sheet meets stringent quality standards. As a result, customers can enjoy products that are not only aesthetically pleasing but also durable and reliable. The seamless integration of technology and manufacturing practices is thus crucial in distinguishing premium manufacturers from their competitors in the market.

Identifying authentic premium manufacturers for high-quality UV PVC marble sheets in 2025 requires a keen eye for detail and knowledge of industry standards. Start by evaluating certifications and standards that the manufacturer adheres to. Look for ISO certifications, which indicate adherence to quality management principles, ensuring that the products meet international standards. A manufacturer that invests in quality control processes is more likely to provide durable and aesthetically pleasing products.

Additionally, it's essential to investigate the manufacturer’s reputation within the industry. Seek out customer reviews and testimonials to understand the experiences of other businesses. A strong track record of reliable service and consistent product quality can be a clear indicator of a premium manufacturer. Networking within industry forums and attending trade shows can also provide insights into established manufacturers who are recognized for their quality and innovation in UV PVC marble sheets. Cultivating these relationships can lead to better partnerships and ensure access to the highest quality materials.