Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

WPC Board, or wood plastic composite board, has gained popularity in various construction and design projects. This innovative material combines the durability of plastic with the natural appeal of wood. WPC Board offers a promising alternative to traditional materials, addressing common issues like rot and insect damage.

One of the key advantages of WPC Board is its resistance to weather conditions. It does not warp or fade easily, making it suitable for both indoor and outdoor applications. Additionally, its maintenance is minimal. Simple cleaning can keep it looking new for years. However, choosing the right quality WPC Board is crucial. Not all products perform the same. Therefore, thorough research is necessary.

People often overlook the environmental benefits of WPC Board. It is made from recycled materials, reducing waste. Still, some are concerned about the longevity of such products compared to solid wood. While WPC Board has its drawbacks, many find it a viable choice for sustainability and aesthetics. It's essential to weigh the pros and cons before making a decision.

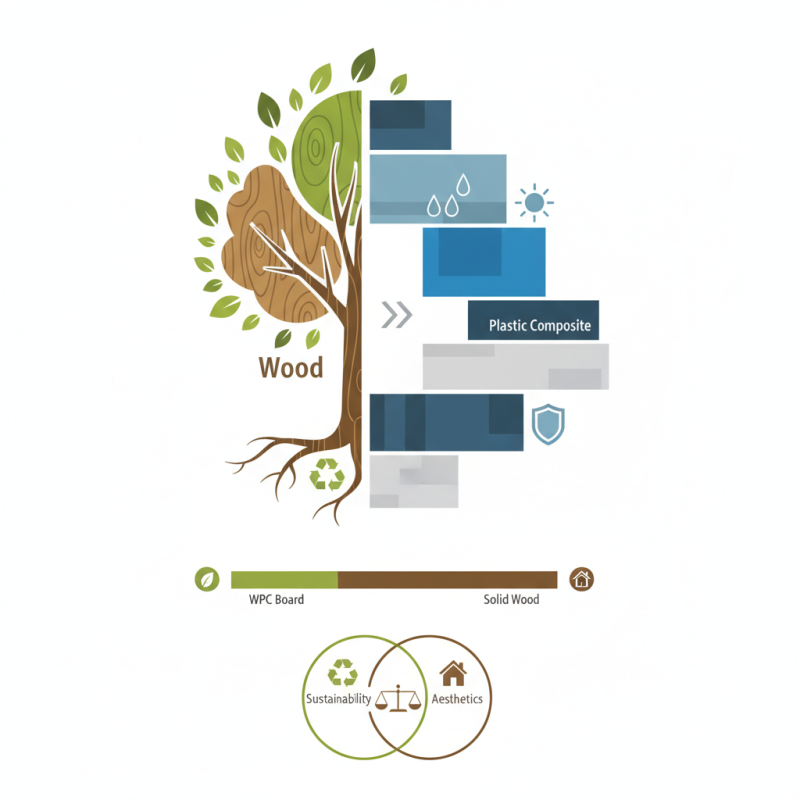

WPC board, or Wood Plastic Composite board, is becoming more popular in various applications. It primarily consists of recycled wood fibers and plastic. The combination of these materials creates a versatile product that offers durability and resistance to weather, insects, and decay.

Research indicates that the global WPC market is expected to reach $10 billion by 2024. This growth is largely driven by the construction and furniture industries. WPC boards are often used for decking, railing, and even outdoor furniture. Their composition allows them to maintain a natural wood appearance while avoiding many of the issues that traditional wood encounters, such as splintering and warping.

However, WPC boards are not without their challenges. They can be heavier than traditional wood, which might complicate installation. Additionally, if not produced correctly, the boards may have inconsistent quality. This raises concerns about their long-term performance. Industry reports suggest a need for better manufacturing practices to enhance the consistency of the product. As awareness of these materials grows, so does the demand for better quality WPC boards.

WPC, or Wood Plastic Composite, boards have gained popularity in construction due to their unique properties. These materials combine wood fibers with plastic, creating a product that is both durable and environmentally friendly. One significant advantage of using WPC boards is their resistance to moisture and insects. This makes them ideal for outdoor projects like decking and fencing.

Another key benefit is their low maintenance requirement. Unlike traditional wood, WPC boards do not require regular painting or sealing. They can be easily cleaned with just soap and water. While it's true that WPC materials may have a higher upfront cost, they tend to save money in the long run. Their longevity and durability can offset those initial expenses.

However, it's worth noting that not all WPC boards are created equal. Some may degrade faster under extreme weather conditions compared to others. This variation can lead to mixed experiences among users. It's essential to research and choose the right type for your specific needs. In some cases, individuals may find the aesthetic appeal lacking, which could impact design choices.

When comparing WPC (Wood Plastic Composite) board with traditional materials, notable differences emerge. Traditional wood, while beautiful and sturdy, often suffers from issues related to moisture and pests. It can warp or rot over time. In contrast, WPC boards offer enhanced durability, resisting such deterioration. They stand firm against moisture, meaning they last longer in various environments.

Additionally, WPC boards require less maintenance than traditional wood. Traditional materials often need regular staining or sealing. This can be time-consuming and expensive. WPC boards, however, can often be cleaned with soap and water. They maintain their appearance with little effort.

Yet, WPC boards are not without flaws. Some users report challenges with color matching in large projects. The aesthetics might not fully replicate natural wood grain. This can be a significant consideration for designers seeking a precise look. While WPC boards present clear advantages, careful thought is essential before choosing the right material for each project.

WPC boards, or Wood Plastic Composites, have gained popularity across various industries due to their versatility. They are made from a blend of wood fibers and plastic, making them an eco-friendly alternative to traditional materials. One prominent application is in the construction industry. WPC boards are used for decking, fencing, and cladding. Their resistance to moisture makes them ideal for outdoor use, reducing maintenance costs over time.

In the furniture sector, WPC boards can be crafted into attractive panels and surfaces. They offer a warm appearance similar to wood but with better durability. This material is also easy to mold and can be shaped into unique designs. However, some original designs may not hold up as well in varying climates. Ensuring proper ventilation is key to avoiding warping and fading.

WPC boards find use in automotive interiors as well. They provide lightweight and aesthetic solutions for car manufacturers. Yet, the balance between weight reduction and strength is crucial. Some manufacturers may overlook this, leading to performance issues. As industries continue to explore WPC boards, understanding their strengths and weaknesses will be essential for future projects.

WPC board, or Wood Plastic Composite, combines wood fibers with plastic materials. This innovative product offers notable advantages, particularly in terms of maintenance and durability. It resists moisture, making it ideal for outdoor projects. Unlike traditional wood, it won't warp, crack, or splinter.

The longevity of WPC boards stems from their resistance to pests and decay. They are less likely to show signs of wear over time. This makes WPC an excellent choice for decking, fencing, and furniture. However, despite their durability, some users report fading colors when exposed to harsh sunlight.

**Tips:** Regular cleaning can help maintain their appearance. You also might want to apply UV protectants periodically. Additionally, consider shade solutions if your project is in direct sunlight. These steps enhance longevity but may still not prevent all discoloration. Remember, some imperfections in WPC are normal, and they can be reflective of the material's unique character.