Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

WPC Board is a versatile material gaining popularity in various industries. It includes wood fibers combined with plastic, making it unique. This material offers excellent durability while being lightweight. WPC boards are eco-friendly, with many options available for sustainable use.

The benefits of WPC boards extend to both aesthetics and functionality. They can be used in outdoor decking, fencing, and furniture. Their resistance to moisture and pests makes them a practical choice. Designers appreciate the variety of colors and textures available.

However, challenges exist in WPC board production and application. Some users report issues with fading colors and surface scratches over time. While it holds many advantages, continual improvement in quality is essential. Exploring these aspects allows for a better understanding of WPC boards and their potential.

WPC board, or wood plastic composite board, combines wood fibers with thermoplastics. This material offers several benefits. It is durable, resistant to moisture, and pests. Studies show that WPC boards can last longer than traditional wood. They offer a lifespan of over 25 years when properly maintained. This durability is crucial for outdoor applications.

The uses of WPC boards are varied. They are popular for decking, siding, and railing systems. According to a recent market analysis, the demand for WPC products has increased by 10% annually. Many homeowners choose WPC for its aesthetic appeal and low maintenance requirements. However, some users report difficulties with color fading and surface scratching.

Applications extend into commercial settings as well. WPC boards are often used in parks and urban furniture. Reports indicate that around 30% of new outdoor constructions use WPC materials. Despite the advancements, challenges remain. Not all manufacturers ensure consistent quality, leading to performance issues in some cases. This inconsistency calls for cautious selection when choosing WPC products.

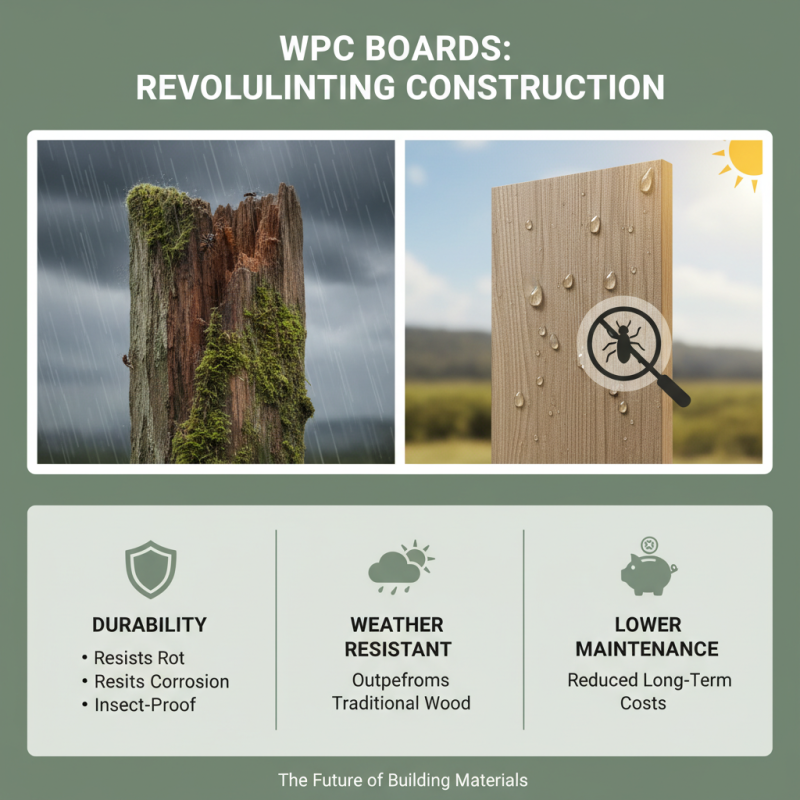

WPC boards, or Wood Plastic Composites, are revolutionizing the construction and design industries. One of their primary advantages is durability. Research shows that WPC boards can withstand harsh weather conditions better than traditional wood. They resist rot, corrosion, and insects. This can lead to lower maintenance costs over time.

Another significant benefit is their eco-friendliness. Many WPC products contain recycled materials, reducing waste. A study indicated that using WPC can decrease carbon footprints by up to 30%. This appeals to environmentally conscious consumers. However, some applications may require specific grades of WPC for maximum performance, which can complicate sourcing.

WPC boards are versatile. They work well for decking, fencing, and interior projects. However, installation can be tricky without proper guidance. Experienced contractors might still prefer traditional materials for certain projects. Yet, the shift towards WPC is clear. As awareness of its benefits grows, more industries will likely embrace its use. The trend illustrates a need for ongoing education about this innovative material.

WPC boards, composed of wood fibers and plastic, have gained traction in various industries. Their sustainability and adaptability make them popular. In construction, about 40% of materials used for decking and fencing are now WPC boards. They mimic natural wood's appearance while offering durability against weather impacts.

In the furniture sector, WPC boards are increasingly utilized for indoor and outdoor applications. Companies report that using WPC boards can reduce maintenance costs by up to 25%. They are lightweight, easy to handle, and require little upkeep, making them suitable for modern designs. However, some manufactures still face challenges ensuring consistent quality.

Landscaping applications are rising, with WPC boards used for planters and garden furniture. According to recent studies, the global demand for WPC boards in landscaping will grow at a CAGR of 10% through 2025. Yet, there are concerns about the environmental impact of plastic content in WPC. Industry leaders must balance sustainability with performance.

| Feature | Details |

|---|---|

| Water Resistance | WPC boards are resistant to moisture and water, making them ideal for outdoor applications. |

| Durability | They offer excellent durability and are resistant to termites, rot, and fungus. |

| Low Maintenance | WPC boards require minimal maintenance compared to traditional wood materials. |

| Eco-Friendly | Made from recycled materials, WPC boards are an environmentally friendly choice. |

| Versatility | Can be used for various applications including decking, fencing, and furniture. |

| Aesthetic Appeal | Available in various colors and textures, resembling natural wood. |

| Cost-Effective | Generally more affordable over time due to lower maintenance and replacement costs. |

WPC boards, or Wood Plastic Composite boards, offer advantages that are significant compared to traditional materials. For instance, they resist moisture, rot, and pests, making them ideal for outdoor applications.

According to the Global Wood Plastic Composite Market Report, the market is expected to grow by 12.9% between 2022 and 2030. This growth is primarily due to the increasing demand for eco-friendly building materials.

In comparison to wood, WPC boards require less maintenance and can last longer. Traditional wood can warp or fade, whereas WPC maintains its appearance for years. Yet, some users report issues with color uniformity, particularly in direct sunlight. While WPC boards provide a durable option, they also come with a higher initial cost. The trade-off between initial investment and long-term savings can be a tricky decision for builders and homeowners.

Recycling options for WPC boards remain limited. While manufacturers promote sustainability, the lifespan at landfills can be concerning. Studies indicate that about 30% of composite waste is not recycled. This presents a challenge for the industry. Stakeholders must prioritize developing robust recycling systems if they wish to enhance the sustainability profile of WPC.

WPC boards, or wood-plastic composites, are gaining attention for their eco-friendly qualities. These materials are made from recycled wood and plastic. Studies show that using WPC can reduce plastic waste by up to 70%. This significant reduction contributes positively to the environment. Additionally, WPC boards require less energy to produce compared to traditional materials.

One critical environmental impact is resource conservation. WPC boards recycle leftover wood fibers and plastic waste. This process diminishes the need for virgin materials. According to industry reports, the demand for WPC is projected to grow by 12% annually. Such growth highlights a shift toward sustainable building materials.

Tips: When choosing materials, consider their source. Look for products that prioritize recycled content. Also, check if companies offset their carbon footprint.

While WPC boards offer numerous benefits, they are not without flaws. Their lifespan can vary based on environmental conditions. In certain applications, they may warp or discolor if exposed to excessive moisture. Understanding these limitations is vital for making informed decisions.