Leading PVC Marble Wall Panel Manufacturers in China | Trusted Industry Experts

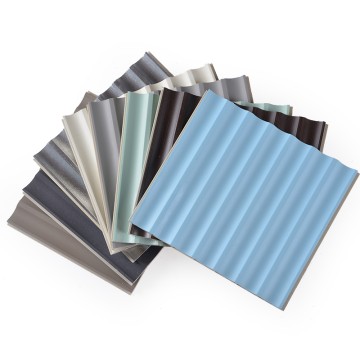

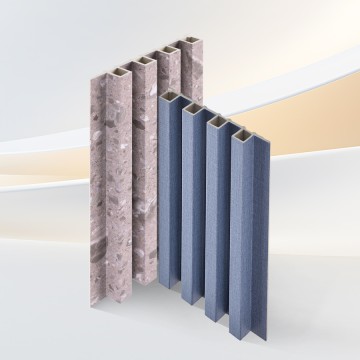

Elevate your interior design with premium PVC marble wall panels from Shandong Xiangying New Materials Technology Co., Ltd. These panels beautifully replicate the elegance of natural marble, providing a striking visual impact while offering practical advantages. Lightweight and easy to install, they are suitable for both residential and commercial spaces. Our water-resistant, durable, and low-maintenance PVC marble wall panels are perfect for kitchens, bathrooms, and living areas. Available in a wide range of colors and patterns, they offer customizability for your environment. Each panel is manufactured to meet high standards of quality and aesthetics, delivering a luxurious appearance without breaking the bank. Transform your spaces with the perfect blend of style and functionality offered by our exquisite PVC marble wall panels.Practical Strategies for Pvc Marble Wall Panel Manufacturer From Concept to Delivery Ahead of the Curve

In today’s competitive market, PVC marble wall panels are gaining immense popularity due to their aesthetic appeal and durability. For manufacturers aiming to stay ahead of the curve, adopting practical strategies from concept to delivery can significantly enhance their market presence and attract global buyers. The journey begins with understanding design trends and consumer preferences, which are crucial in shaping innovative product offerings. Engaging in thorough market research allows manufacturers to tailor their panels to meet diverse client needs while ensuring compliance with industry standards. Moreover, leveraging advanced technology in production processes can streamline operations and improve product quality. Investing in high-grade raw materials, along with automated manufacturing systems, ensures consistency and reliability in the final output. As a company with over a decade of experience and a commitment to service, we prioritize mutual benefits and win-win cooperation. This dedication not only builds trust with our partners but also reinforces our goal to deliver the best products to our customers. Finally, efficient logistics and timely delivery play a vital role in maintaining customer satisfaction. Establishing strong partnerships with shipping companies and optimizing supply chain management can minimize delays and enhance the overall customer experience. By focusing on these key areas, PVC marble wall panel manufacturers can not only meet but exceed global buyers' expectations, ensuring long-lasting relationships and sustained growth in the industry.

Practical Strategies for PVC Marble Wall Panel Manufacturer From Concept to Delivery Ahead of the Curve

| Strategy | Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| Market Research | Conduct in-depth analysis of current market trends and customer preferences. | Identify new opportunities and tailor products to meet demand. | 1-2 months |

| Design Innovation | Develop new and unique designs for PVC marble wall panels. | Increase product appeal and differentiation. | 2-3 months |

| Quality Assurance | Implement strict quality control processes during manufacturing. | Enhance product reliability and customer satisfaction. | Ongoing |

| Supply Chain Optimization | Streamline supplier relationships and logistics management. | Reduce costs and improve delivery times. | 3-6 months |

| Marketing Strategy | Develop a comprehensive marketing plan to reach target customers. | Increase market penetration and sales volume. | 2-4 months |

| Customer Feedback Loop | Establish a system for collecting and analyzing customer feedback. | Improve product offerings based on customer insights. | Ongoing |

How To Find The Best Pvc Marble Wall Panel Manufacturer Industry Giant Factory-Direct Excellence

M

Michael Thompson

Absolutely loved the product! The after-sales staff are knowledgeable and addressed my queries promptly. A pleasant buying experience!

28 May 2025

A

Ava Lewis

Excellent quality! The customer service was impressive, as they were proactive in following up after my purchase.

15 June 2025

H

Harper Thompson

This product is top-quality! The customer support team walked me through every step with expertise.

07 July 2025

C

Chloe Hall

This product stands out for its quality, and the after-sales service was friendly and diligent.

01 June 2025

R

Robert Sinclair

The durability of this product is impressive. I was pleasantly surprised by the level of support I received post-purchase.

14 July 2025

E

Emily Foster

The craftsmanship of the item is truly exemplary. The follow-up service by the team demonstrated their commitment to customer satisfaction.

25 June 2025

Hot Selling

Hot Selling