WPC Ceiling Panel Manufacturers in China: Leading Suppliers & Top Factories

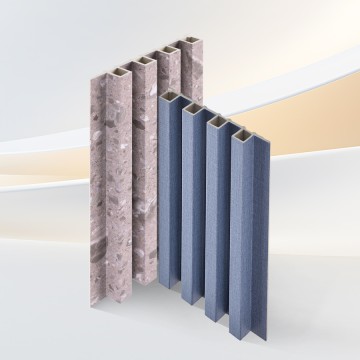

Elevate your interior design with premium WPC Ceiling Panels from Shandong Xiangying New Materials Technology Co., Ltd. Our factory specializes in providing innovative building materials, offering a wide selection of ceiling solutions that blend aesthetics with durability. Made from wood-plastic composites, our panels feature an elegant finish and are resistant to moisture, termites, and decay, making them ideal for humid environments. With various styles, colors, and textures available, customization is effortless. These panels are easy to install and maintain, suitable for both residential and commercial applications. Committed to sustainability, our materials help reduce the impact on deforestation while delivering superior performance. For renovation or new design projects, choose Shandong Xiangying’s WPC ceiling panels as a stylish and resilient solution that enhances any space. Experience the seamless integration of nature and technology.Best Methods To Wpc Ceiling Panel Factories Dominates Industry Leaders

In the rapidly evolving construction materials industry, WPC (Wood Plastic Composite) ceiling panels have emerged as a leading choice for both aesthetics and durability. As the demand for high-quality building materials grows, factories specializing in WPC ceiling panels have mastered several best methods to dominate in this competitive landscape. Key among these methods is a commitment to service and integrity, ensuring that clients receive not only exceptional products but also a reliable partnership. With over ten years of industry experience, our company exemplifies this approach by continuously refining our manufacturing processes and engaging in open communication with customers. This dedication to quality craftsmanship and customer satisfaction has garnered us a loyal global client base. We understand that trust is the cornerstone of any successful business relationship, and we strive to uphold this principle through mutual benefit and win-win cooperation. As the industry evolves, we remain focused on innovation, ensuring our products not only meet but exceed market standards, ultimately positioning us as leaders in the WPC ceiling panel sector. For global procurement professionals seeking reliable partners, aligning with established WPC ceiling panel factories that prioritize integrity and product excellence is crucial. By choosing suppliers who are committed to long-term collaboration and customer needs, businesses can ensure they are equipped with the best materials to meet their construction goals. Our unwavering dedication to creating the finest WPC products, supported by years of expertise, positions us as the ideal choice for those looking to enhance their projects with top-tier ceiling solutions.

Best Methods To Wpc Ceiling Panel Factories Dominates Industry Leaders

| Factory Location | Production Capacity (units/year) | Quality Certification | Sustainability Practices | Export Markets |

|---|---|---|---|---|

| North America | 500,000 | ISO 9001, ISO 14001 | Recycled Materials Usage | USA, Canada |

| Europe | 350,000 | FSC Certified | Energy Efficient Production | Germany, France, UK |

| Asia | 750,000 | CE Marking | Water Conservation Techniques | Japan, China, India |

| Australia | 200,000 | Green Building Certification | Reduced Emissions Plan | New Zealand, Pacific Islands |

Not to Be Missed Wpc Ceiling Panel Factories Exceeds Industry Benchmarks Application

N

Natalie Garcia

Impressive craftsmanship! The after-sales support team was knowledgeable, polite, and went out of their way to explain everything.

03 July 2025

B

Brian Hall

The quality is outstanding! The team that assisted me after my purchase was both friendly and knowledgeable.

25 July 2025

H

Hannah Perez

I’m thrilled with my purchase! The quality is unbeatable and customer support was exceptional.

01 June 2025

L

Lily White

Fantastic quality with excellent after-sales service! The team was very competent and friendly, which made all the difference.

11 June 2025

C

Chloe Hall

This product stands out for its quality, and the after-sales service was friendly and diligent.

01 June 2025

O

Oliver King

Quality product! The customer service team knew exactly how to assist with my inquiries.

03 June 2025

Hot Selling

Hot Selling