Wholesale WPC Fluted Panels - Reliable Manufacturer & Supplier for Quality Solutions

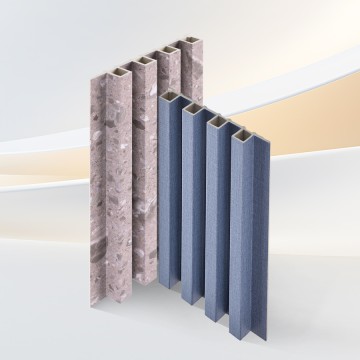

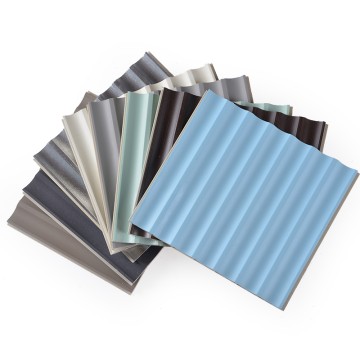

WPC Fluted Panels are a leading choice in modern construction and design, known for their durability and elegance. Shandong Xiangying New Materials Technology Co., Ltd. offers premium WPC fluted panels that merge aesthetics with functionality. Made from a composite of wood fibers and recycled plastics, these panels are eco-friendly and offer resistance to moisture, decay, and pests. Suitable for both interior and exterior uses, they add unique texture and visual depth to any environment. Available in a variety of colors and finishes, the panels can be customized to meet individual design preferences. Each product undergoes rigorous testing to ensure adherence to stringent quality standards, ensuring both longevity and performance. Elevate your projects with this sustainable and stylish material, expertly crafted by industry leaders, achieving a harmonious blend of innovation and tradition.Why Opt For Wpc Fluted Panel Manufacturers Factory From Concept to Delivery

In the ever-evolving landscape of construction and design, choosing the right materials can significantly impact the success of your project. This is where WPC fluted panels come into play, offering an elegant yet durable solution for various applications. When it comes to sourcing these panels, partnering with a reliable manufacturer is essential to ensure quality and consistency. Our factory has been committed to providing exceptional service and top-notch products for over a decade, specializing in WPC fluted panels that meet the highest industry standards. By opting for our WPC fluted panel manufacturing services, you gain access to a wealth of experience and expertise. Our production process is streamlined, from conceptual design to delivery, ensuring that every step is handled with precision and care. We prioritize transparency and communication, fostering a collaborative environment where our clients can rely on our support throughout their projects. Our tenet of "service and sincerity in exchange for your trust" drives us to exceed expectations, paving the way for mutual benefit and win-win cooperation. Choosing our WPC fluted panels not only guarantees superior quality but also promotes sustainability through the use of eco-friendly materials. Whether you're an architect, contractor, or designer, partnering with our factory means you can focus on realizing your vision, while we take care of the rest. Let us help you elevate your projects with our expertly crafted WPC fluted panels—where innovation meets reliability, ensuring your complete satisfaction from concept to delivery.

Why Opt For WPC Fluted Panel Manufacturers Factory From Concept to Delivery

| Dimension | Material Type | Color Options | Application | Lead Time (Days) |

|---|---|---|---|---|

| 1200x2400 mm | WPC (Wood Plastic Composite) | Mahogany, Light Grey, Beige | Interior Walls, Ceilings | 15 |

| 600x1200 mm | WPC (Wood Plastic Composite) | Dark Oak, White, Black | Exterior Cladding, Decking | 20 |

| 300x300 mm | WPC (Wood Plastic Composite) | Teak, Navy Blue, Cream | Furniture Panels, Acoustic Walls | 10 |

| 900x1800 mm | WPC (Wood Plastic Composite) | Charcoal Grey, Maple, Walnut | Partition Walls, Decorative Panels | 25 |

Must-See List Wpc Fluted Panel Manufacturers Factory-Direct Excellence in 2025

J

James Carter

The attention to detail in the product construction is remarkable. Plus, the professionalism of the after-sales support made the purchase even more satisfactory.

23 June 2025

M

Megan Adams

Top-quality product! The after-sales service representatives were friendly and attentive, making the whole process easy.

09 June 2025

C

Christopher Young

Perfect purchase! The quality is outstanding, and the service team exhibited a high level of professionalism.

28 May 2025

M

Mason Walker

Incredible quality and service. The support staff provided precise assistance—I felt valued.

26 July 2025

A

Aubrey Edwards

This was a great investment! The quality is amazing and the customer service is superb.

26 June 2025

C

Christopher Reed

Quality that speaks for itself! The after-sales service was handled with great professionalism.

21 June 2025

Hot Selling

Hot Selling